VP7 Vertical Pouch

Packaging Machine

VP7 is a tabletop pouch making machine used for packaging unit dose solids, liquids or cut to length films. The machine has 2 rotary sealing wheels. The wheels are made to fit the type of package being made.

Speed: Variable from 0 to 60 packages per minute.

Package Size: Package width from 1" to 2".

Package length from 1 1/2" to 7"

Single and variable packages cut-offs or perforated are available.

Packaging Material: Any heat sealable material can be run on the machine (paper laminate, aluminum foil). The machine will run unprinted film or random printed film.

Utilities: 110 V AC 8 A (220V is also available) Air 60PSI 3CFM

The following product feeders are available:

- Tablet/ Capsule feeder

- Liquid or Cream dispenser

- Cut to length feeder

Optional attachments:

- Reciprocating pad printing coder

- Non contact coder

- Stand on wheels

- Enclosed cabinet with compressor

- Tablet or capsule feeder

- Diving nozzle for liquid filling

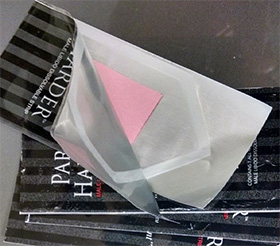

AS701 StripPack Machine

StripPack-AS701 is a machine designed to package edible film strips into individual pouches. The machine can handle various printed and heat sealable pouching materials for the pouch, and soluble film can be supported or unsupported. The machine can be used in automatic or semiautomatic mode. In semiautomatic, the operator actuates a foot pedal to initiate each cycle and this mode also allows provisions for placing precut soluble film strips manually (for small runs).

Main components of the machine are:

- Pouch material unwinders (2 per machine)

- Soluble film cut and feed mechanism

- Pouch sealing mechanism

- Print registration drive

- Cutting mechanism

Technical Specifications:

- Maximum roll diameter for the pouch material and for the soluble film is 14”

- Utilities require Electrical 110/220 V at 15 A and compressed air at minimum 80 PSI

- Machine footprint dimensions are 60”L x 36“ W x 36”H

- Production rate 16 to 22 pouches per minute (single strip per pouch)

- All product contact parts are stainless steel or FDA approved materials

- End-of-roll sensors

Optional devices that can be incorporated include:

- Date and batch coder

- Vision system to verify for presence of strip in the pouch