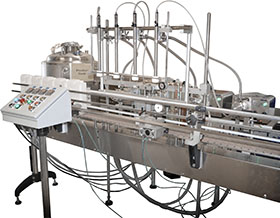

4 Head Automatic Filling Line

4 Head Automatic Filling Line is a complete automated filling system.

With a rugged stainless-steel base, this unit can accommodate up to 4 filling units.

Features:

- Adjustable bottle indexing system

- No bottle/ No filling safety device

- Bottle neck clamp attachment

- PLC controller

- Tool-less changeover

Available in partial or full diving system.

Explosion-Proof Filler

PF8 Tabletop Piston Filler

PF8 Tabletop Piston Filler for accurate filling of heavy creams and pastes (non free-flowing) products.

This volumetric filler is air actuated and has a programmable control system that allows the filler to be run manually or automatically, easily integrating with other packaging equipment.

Features:

- All product contact parts are made of stainless steel

- Filling capacity, single stroke 1/4 oz to 8oz. Other filling capacity pistons are available.

- Five Gallon Overhead Hopper with sanitary, Tri-Clamp fittings

- Available in either 110V or 220V

- Easy disassembling for cleaning

Options Include:

- Table top mounting kit

- Alternate filling nozzles

- Dispensing tubes and pistons for higher volumes

- Heaters for hot fills

- Product mixers for hopper

- Automatic container lifters and spinners

- Pneumatic lift S.S. table

Peristaltic Filler Flexopump-1

FLEXOPUMP-1 is a table top heavy duty filler. This filler has a ½ HP motor. Fill from 10 ml up to 4 liter with an accuracy better than .25% of fill volume. The filler rollers are mounted on sealed pre-lubricated bearing for a long life. The machine comes with a foot pedal and can easily be integrated with a conveyor or indexing table for fully automatic run. Various tubing materials can be used with the filler (1/8 to 3/8 OD).

Functions available:

- Power ON/OFF

- Single fill or automatic mode selector

- Dispensing volume set with an electronic counter with digital display

- Dispensing speed adjustable

- Repeat cycle timing adjustable.

Power requirements 110V 10A

Power Fillit Gear Pump Filler

The filler includes a 1/2 hp variable speed drive, precision fill volume encoder, dial up volume control, and recycle time for continuous filling. Foot switch operated. Positive shut off nozzle. The filler is suited for filling salad dressing, creams, lotions and gels. The machine has a 30L hopper. The lobe pump can handle some chunky products.

Fillit Gear Pump Filler

This filler includes a 1/4 hp variable speed drive, precision fill volume encoder, dial up volume control, and recycle time for continuous filling. Foot switch operated. Positive shut off nozzle. The filler is suited for filling water, wine, shampoo, oils, sauces, syrups, etc.

Vial Filler for Liquids and Creams

Semiautomatic Cap Tightener

The Kapit bench top semiautomatic cap torquer is ideally suited for small production runs, lab/research areas, and other low production situations. By simply clamping the torquer to any existing conveyor or work station, the torquer may be used as a capper, re-torquer or cap removal.

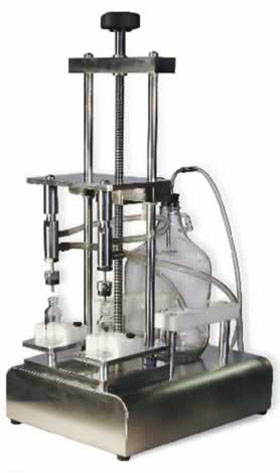

Microfiller-20

Microfill-20 is an accurate filler for Milliliter volumes - Filling vials, small bottles, dosing active ingredients or flavors, etc., and can handle low viscosity liquids such as (water, oil, alcohol etc.). The machine is air actuated making is suitable for explosion proof filling. All product contact parts are stainless steel, FDA approved plastic or glass. The dispenser is a glass with graduation in Milliliters. The control mechanism allows for setting the fill volume to a high accuracy. Depending on the fill volume the speed is between 14 to 24 containers per minute. All parts in contact with the product can be easily disassembled for cleaning.

The following dispensing pistons are available:

- 0 to 10ML, 0 to 20 ML and 0 to 50 ML.

- For larger dispensing volume we have the Microfiller-100 which can fill volumes from 0 to 100 ML and 0 to 200ml.

AE Vacuum Filler

Ideal for filling nail polish, nail polish remover, perfumes and alcohol-based or volatile liquids.

The new AE Vacuum Filler is a semi-automatic, completely pneumatic system designed for safe packaging of any flammable free-flowing product. The AE Vacuum Filler also simplifies the filling of narrow long necked bottles by creating a vacuum effect, which draws the product from your storage tank into the bottle. After reaching the correct level, excess product is drawn into the integrated vacuum chamber for recycling.

With its dual nozzle design, the AE Vacuum Filler enables you to fill two bottles simultaneously, translating into faster production speeds.

The AE Vacuum Filler is built on a stainless steel base and all product contact components are made of non-corrosive materials. All pneumatic, this filler requires only compressed air (60 psi/6 cfm).